Polybutylene terephthalate (PBT) resins are often employed in applications where high resistance to environmental conditions is required. However, PBT is susceptible to hydrolytic degradation caused by humidity combined to high temperature (e.g. above 85% RH and 85°C).

PBT, in fact, is obtained by polycondensation reaction of terephthalic acid or dimethyl terephthalate and 1,4-butanediol, with the release of water. In high humidity and temperature conditions, this reaction can be reversed and the polymer chain is fragmented, with appreciable consequences on the durability of the component.

For this reason, Taro Plast developed TAROLOX 10 I product family, which improves the resistance of the PBT compounds to hydrolysis.

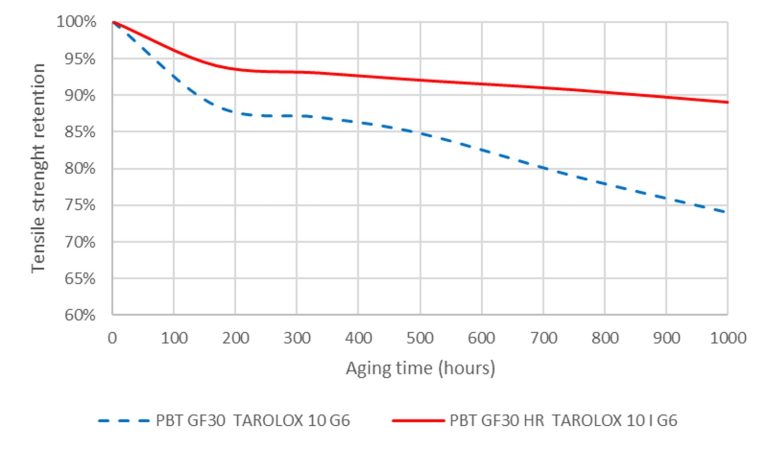

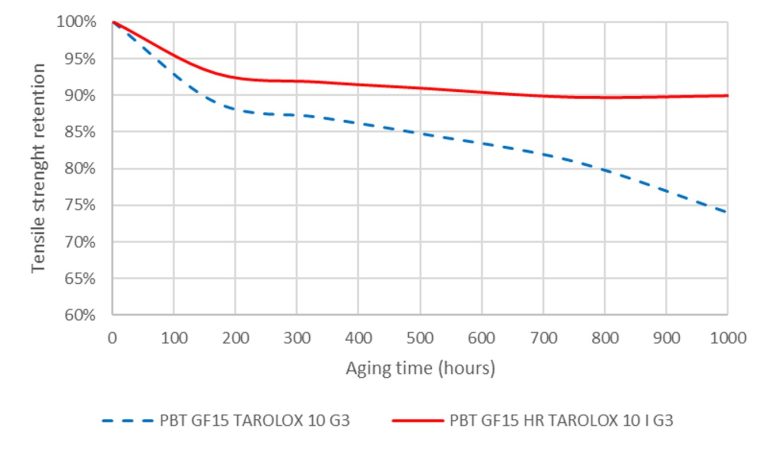

Testing of the product has been performed under very severe conditions, to accelerate the phenomena and appreciate the difference between standard and stabilized grades.

In the charts below we compare the aging behaviour of standard PBT reinforced with 15% and 30% glass fibre (TAROLOX 10 G3 and TAROLOX 10 G6) with the hydrolysis stabilized grades TAROLOX 10 I G3 and TAROLOX 10 I G6.

Tensile strength retention after immersion in water at 85°C; PBT GF30 with hydrolysis resistance (TAROLOX 10 I G6) compared to standard formulation of PBT GF30 (TAROLOX 10 G6).

Tensile strength retention after immersion in water at 85°C; PBT GF15 with hydrolysis resistance (TAROLOX 10 I G3) compared to standard formulation of PBT GF15 (TAROLOX 10 G3).

Aging of products with hydrolysis stability proceeds more slowly, which guarantees longer service life to the components.

TAROLOX 10 I can find application in automotive electrical connectors, switches, sensor systems, housings.

TAROLOX 10 I is available in natural and black colour, with 15%, 20% and 30% glass fibre reinforcement.

Do not hesitate to contact Taro Plast for further information.